All ERP products are moving to SAP, the most talked-about SAP innovation in recent times. This evolution intensifies the demands on SAP EWM to best leverage the features and capabilities of the SAP HANA database. EWM was developed from the ground up as a new Warehouse Management System option for SAP customers delivering enhanced functionality over ERP WM for more complex distribution processes needed as part of integrated supply chain networks. SAP EWM System training will help you in building your career as an Industry expert by giving you a solid foundation and comprehensive overview of SAP EWM.

Description

SAP EWM (Extended Warehouse Management) is a unified software solution by SAP for flexible, automated support for processing various goods movement and managing stock in the warehouse. EWM module supports users with planned and efficient processing of complex logistics processes. The principal components within SAP EWM (SAP Extended Warehouse Management) include warehouse management (SAP Extended Warehouse Management) and material flow control (SAP Material Flow System). The main process in a Warehouse is incoming and outgoing materials, goods receipt and goods issue, fulfill customer orders, and distribution of goods. When a company doesn’t store any goods, then there is no need for Warehouse management to manage goods. SAP EWM is used to efficiently manage inventory in the Warehouse and for supporting the processing of goods movement. It allows the company to control its Warehouse inbound and outbound processes and movement of goods in the Warehouse.

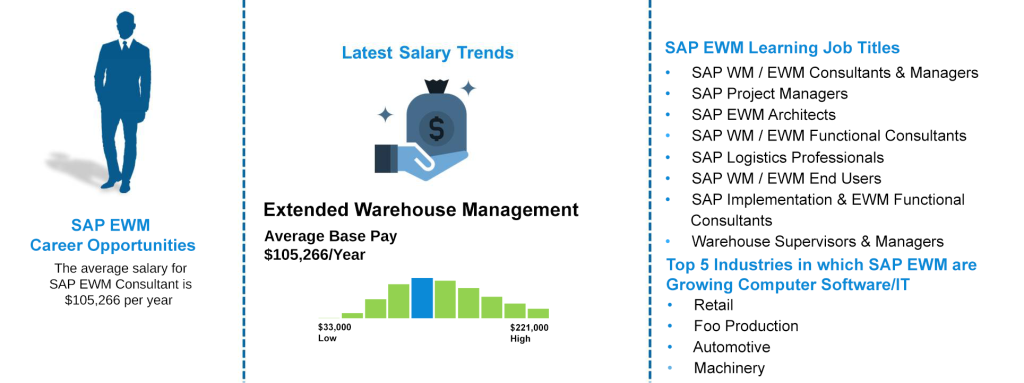

Job Outlook

Objectives

After the completion of this course, Trainee will:

- Insights on Basic ERP and EWM Integration

- Gain knowledge on Warehouse Structure and EWM Master Data

- Understand Inbound processing using EWM

- Learn QIE and ERP Quality Management

- Gain knowledge Good Receipts Process

- Understand the concept of Yard Management in Shipping and Receiving

- Learn how to Integrate Delivery Document and create a rule for Warehouse order

- Understand how to Post Changes, Stock Transfers and Replenishment

Pre-requisites

It is recommended that the trainee should have the following:

- Prior exposure to SAP Vendor Management

- Basic Knowledge of Resource Optimization

Who should attend this Training?

This is one of the most valued and respected professional requirements for professionals who build robust solutions to manage warehouse functions in an organization. This professional certification course is also best suited for:

- SAP WM / EWM Consultants & Managers

- SAP Project Managers

- SAP EWM Architects

- SAP WM / EWM Functional Consultants

- SAP Logistics Professionals

- SAP WM / EWM End Users

- SAP Implementation & EWM Functional Consultants

- Warehouse Supervisors and Managers

Unit 1: Org. Units and System Integration

- Organizational Units

- Basic ERP and EWM Integration

Unit 2: Warehouse Structure and EWM Master Data

- EWM Structural Elements – Storage Types, Storage Sections, Storage Bins, Work centers, Activity Areas and etc.

- EWM Master Data – Product Master, Packaging Specifications, etc.

Unit 3: Warehouse Monitor and RF Framework

- Resource and Queue Management

- Configuration settings for RF

- Warehouse Monitor, Easy Graphics Framework and Warehouse Cockpit

Unit 4: Goods Receipt Process

- Inbound Processing Using EWM

- QIE and ERP Quality Management

- Slotting and Rearrangement

- Availability Groups for Inventory Management

- Direct Put-away Configuration and Put-away Strategies

Unit 5: Goods Issue Process

- Outbound Delivery Processing using EWM

- Wave Processing

- Direct Outbound deliveries

- Stock Removal Strategies

- Exception Handling and Pick Denial

- Batch Management

- Advance Production Integration

Unit 6: Shipping and Receiving

Yard Management

Unit 7: Delivery Document Customizing and Warehouse Order Creation Rule

- Delivery Document Integration

- Warehouse Order Creation Rule

Unit 8: Storage Control

- Storage Control Concepts

- Process-oriented Storage Control

- Layout-oriented Storage Control

Unit 9: Posting Changes, Stock Transfers and Replenishment

- Posting Changes and Stock Transfers

- Ad Hoc Movements and Replenishment

Unit 10: Physical Inventory

- Periodic Physical Inventory Procedure

- Processing of Physical Inventory Documents

- Difference Analysis

- Reports in Physical Inventory

Unit 11: Cross Topics

- Labor Management

- PPF Action Settings

- Value-added services and Kitting

- Cross Docking

- Material Flow Systems (MFS)

Your Content Goes Here